Description

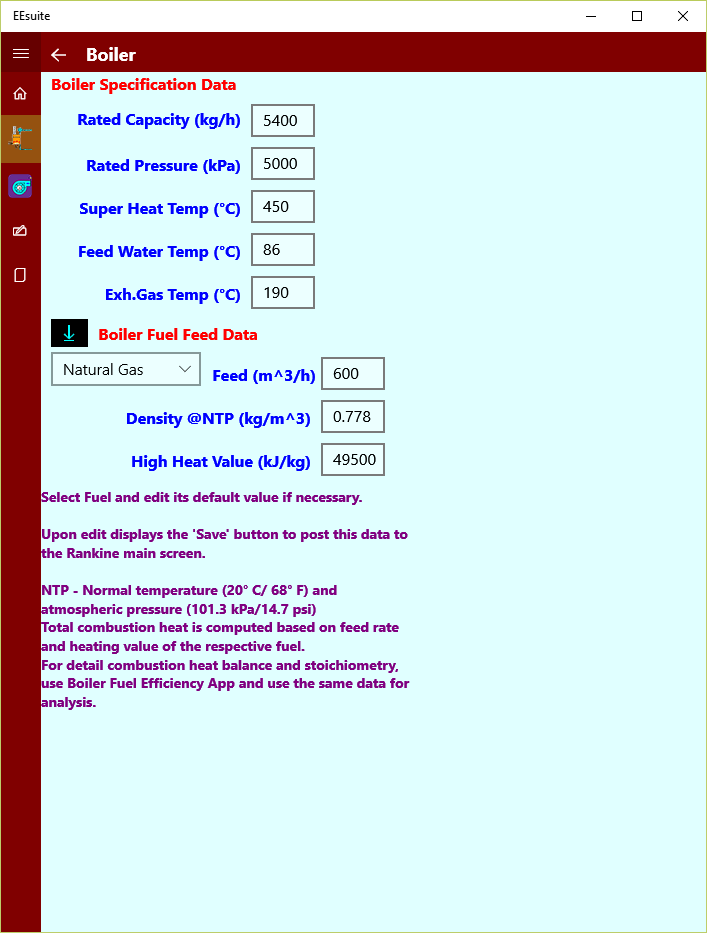

This is a suite of twelve different apps published already are put together to facilitate as a tool for performing energy efficiency studies in energy intensive process industries such as pulp and paper, sugar, petroleum etc. This can be very helpful to energy engineers and auditors in assessing the potential savings as well as to identify areas for improvement in individual devices such as boilers, pumps, compressors, fans and heat exchangers. Besides it can save over 60% of total cost of individual apps provided in this suite.

The suite consists of four supporting apps, five apps covering individual devices and three apps covering basic energy conversion cycles. A brief description of the individual app is given as follows.

Supporting Apps:

-

Thermo-Physical Properties

This app provides thermo-physical property data for 18 most common fluids such as water, air, steam, oil and gases etc. employed in industrial applications. The property data helps in computation of various parameters pertaining to the flow system design involving heat and energy transfers. This App can become very handy for engineers and students dealing with Thermodynamics (steam table), Fluid mechanics and Heat transfers as a quick reference guide for thermal property data. Humid air Psychrometric chart data is also provided for the benefit of HVAC engineers as well. -

Fluid ΔP (Pressure Drop)

App computes pressure loss in transmission of fluids in industrial applications. Users can pick from a list of fifteen most common fluids, ten pipe schedules and sizes with twelve different material of construction to determine overall pressure loss. A judicious selection of pipe size is often a tradeoff between initial cost and subsequent energy cost involved in transmission of fluid from one point to another. Therefore, the app can be a helpful tool for practicing engineers and designers in analyzing different matrix. -

Orifice flow

This app facilitates measurement of fluid flow in pipes and conduits using orifice plates that are very common in industrial applications. This app quickly computes the flow rates for liquid and gases based on standard parameters as per the model shown. Users can pick any fluid from a list of fifteen most common fluids used in industrial applications. Therefore, this app can be a very helpful tool for practicing engineers and designers in measurement of flows in pipes and conduits. -

Engineering unit conversion

Engineering Unit Conversion app helps to convert units associated in engineering conventions and computations from SI to USCS and vice-verse. App covers about 18 different Unit categories commonly used in most engineering applications.

Device Apps:

-

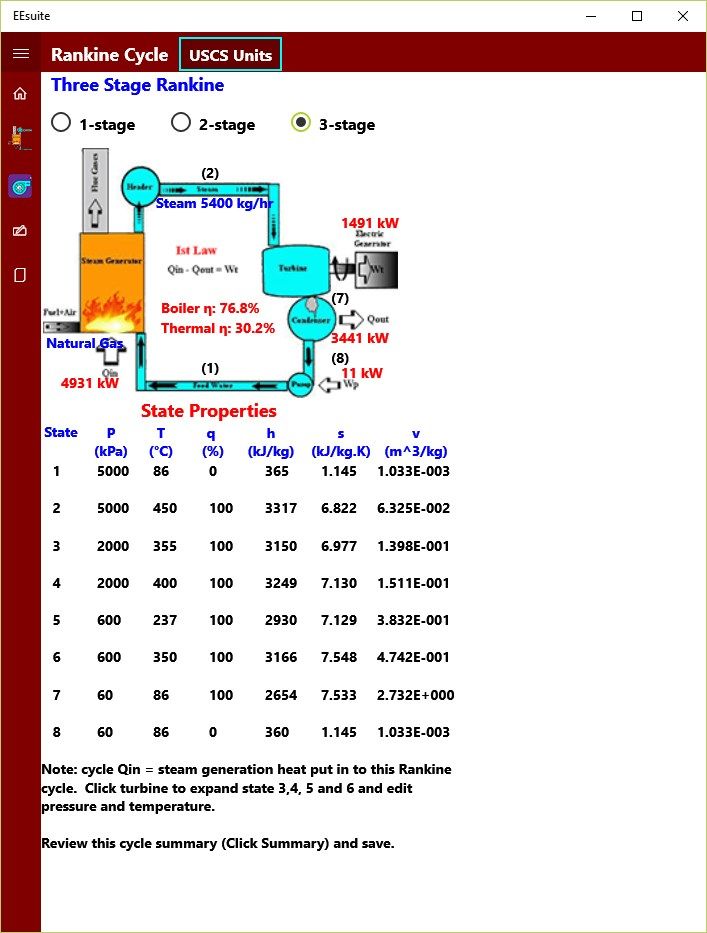

Boiler Fuel Efficiency

This app helps to run a quick preliminary audit on any water tube industrial boiler. Users can select different types of fuels such as coal, oil and gases with specific compositions and heating values to evaluate efficiency and performance in boilers. The combustion model computes the efficiency and displays the heat balance sheet as well as flue gas analysis and stoichiometry of the combustion process. -

Centrifugal Pump Specification

This app guides to determine the three key factors of a centrifugal pump design specification such as ‘System Head’, ‘NPSHA’ and ‘Sizing’ in order to realize its energy saving potential. Selecting a right spec for the given application is often iterative process and is very essential for its energy efficiency and long-term satisfactory performance -

Fan Specification Performance

This app evaluates the fan specification of any given application based on performance characteristics such as flow rate, static pressure, shaft power, and fan efficiency. It also determines the average duct velocity and duct pressure loss, permissible duct leakage rate for a given duct class that are very critical to satisfactory performance and energy efficiency. -

Compressor Performance

This app computes various performance indices in a single stage Industrial Air Compressors. Compressed Air system is one of the energy intensive utility often ignored once it is installed and running. It is also one of the least energy efficient as it works between loading and unloading pressure settings. Hence app uses an average pressure ratio for its general performance analysis. Further, app also helps in running quick tests to estimate both FAD and leakage in a given compressed air systems in order to assess the potential energy savings. -

Heat Exchanger Performance

This App helps to evaluate performance in a shell and tube heat exchanger in terms of its over all heat transfer U-coefficient. It also helps to determine different maintenance requirements like cleaning schedule based on changes in its performance characteristics due to degradation.

Energy Cycles

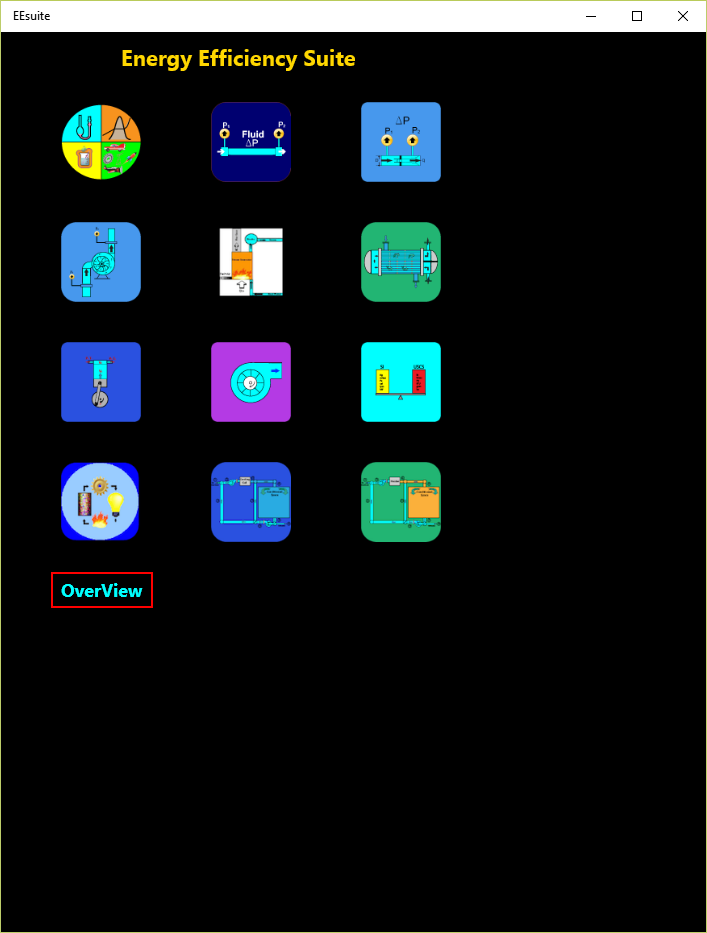

App covers following three basic energy conversion models and evaluates performance associated with its model elements, sizing and conversion efficiencies. Thus provides a quick bird’s eye view of a total system for energy saving potential as well as system optimization.

-

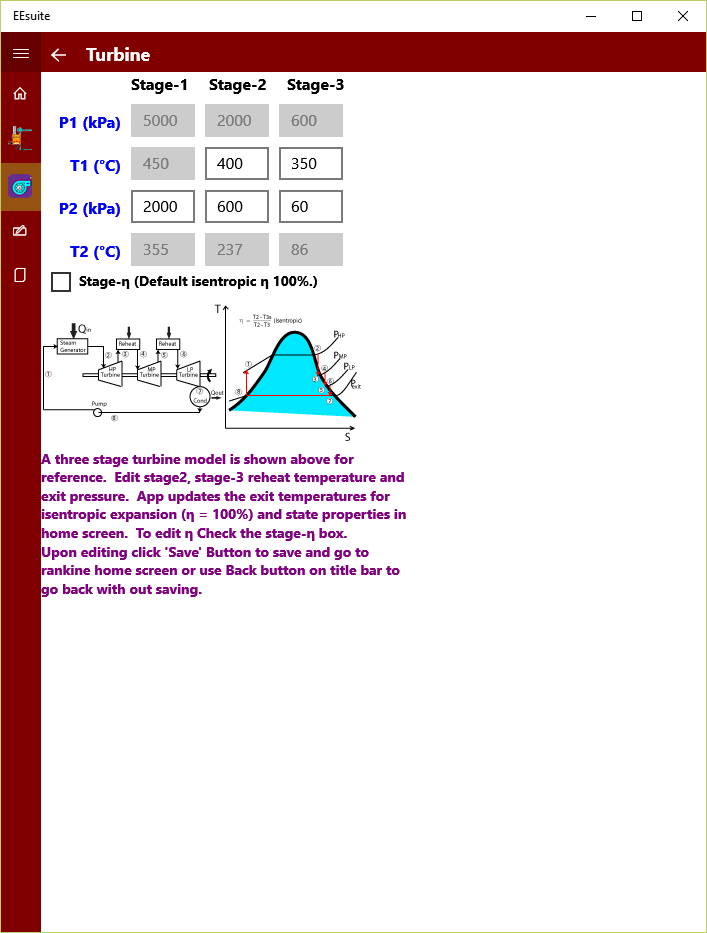

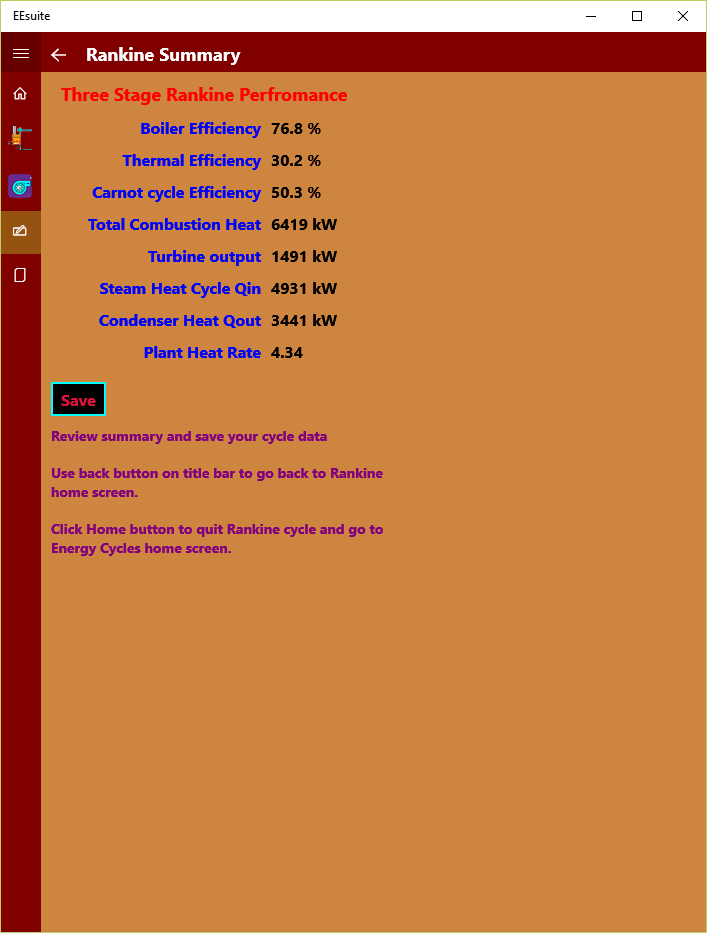

Rankine Cycle

Model covers a boiler (Fossil fuel), turbine(single stage/two stage/three stage), condenser (shell and tube) and a feed pump. The model presents thermodynamic property data of each state and evaluates boiler efficiency, thermal efficiency with overall plant heat rates. -

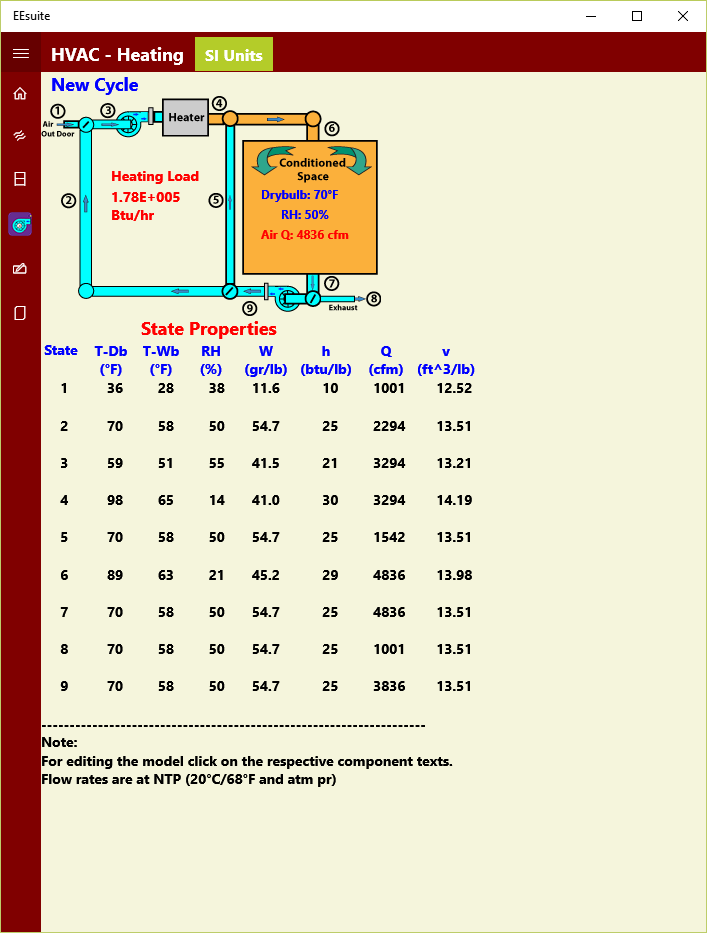

HVAC Heating Cycle

Model covers outdoor air, fan-coil , conditioned space and return air. App helps determine total heat load under 10 different categories as per ASHRAE guide lines . The model presents humid air property data of each state and evaluates total heating load and fan-coil system performance. -

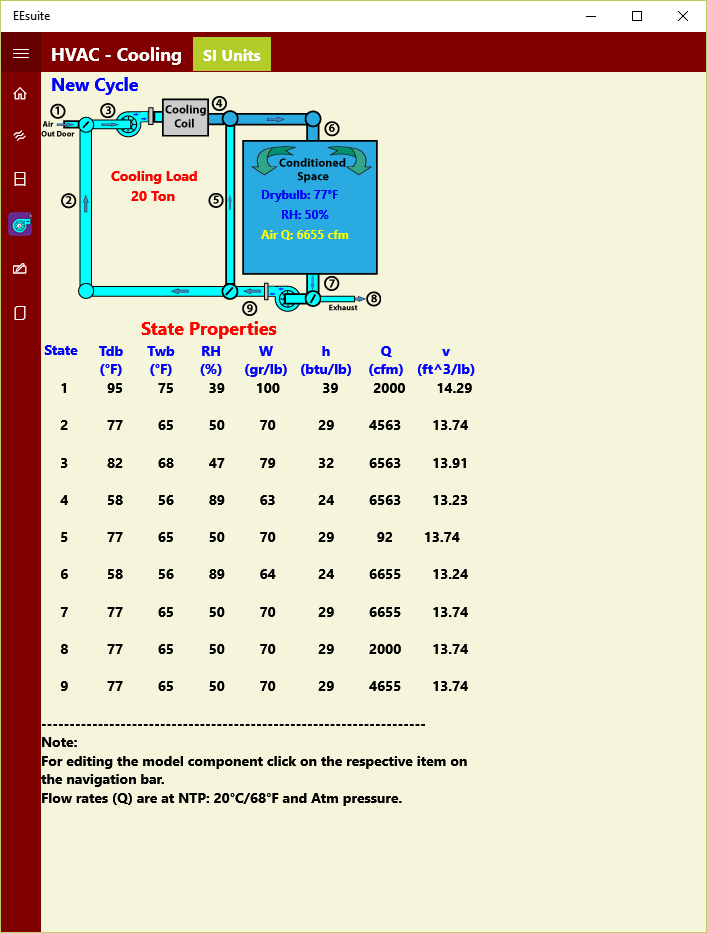

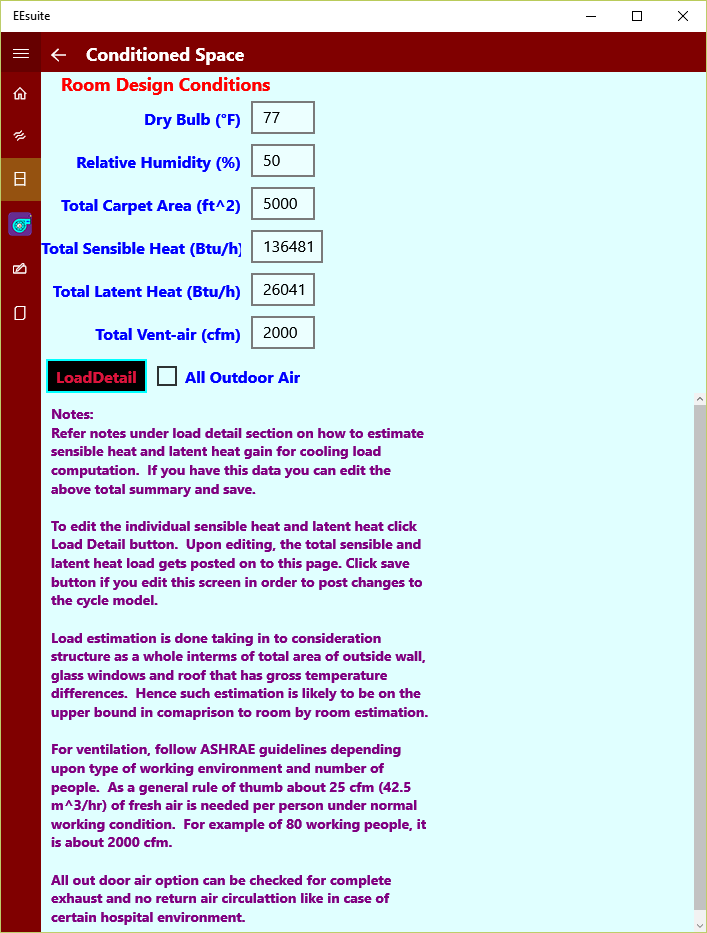

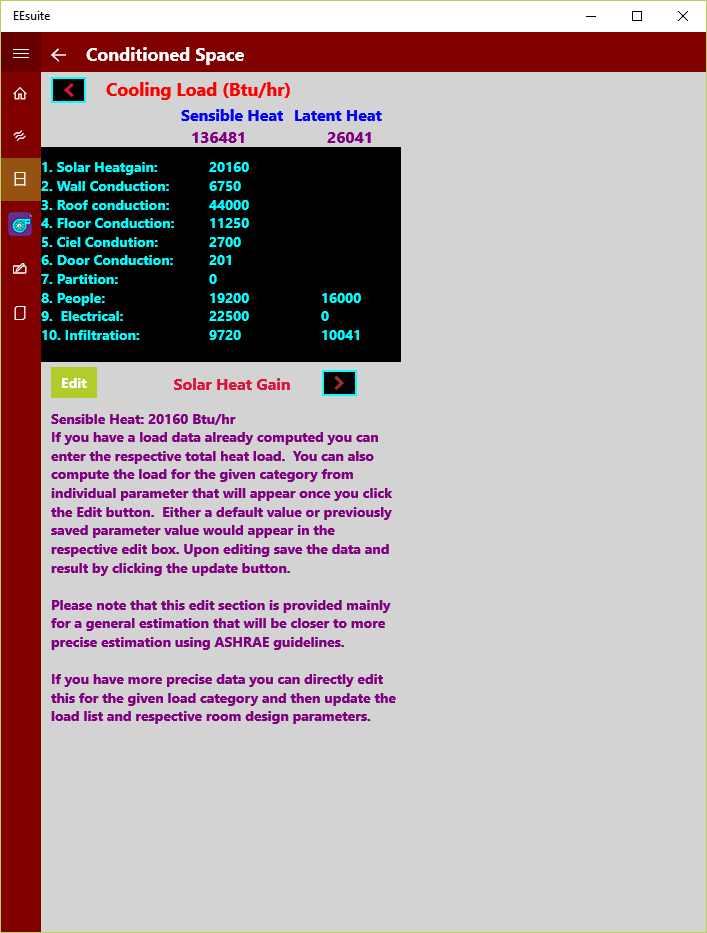

HVAC cooling Cycle

Model covers outdoor air, fan-coil , conditioned space and return air. App helps determine total cooling load under 10 different categories as per ASHRAE guide lines The model presents humid air property data of each state and evaluates total cooling load and fan-coil system performance.

Screen shots covers mainly the above energy cycle models. For more details on individual apps please refer to the respective app descriptions and screen shots presented separately in the Windows store. Alternatively you may also visit our following web site.

www.flowjoule.coom

This application suite will be constantly updated and all future updates will be available for downloading at no extra cost.

-

A reference guide for thermo-physical properties of fluids, steam table and humid air properties for HVAC applications

-

Serves as a tool for conducting energy audit studies in chemical and process industries.

-

Covers critical static and rotating equipment specification design and performance analysis.

-

Helps energy engineers and auditors to assess the potential savings as well as to identify areas for improvement.