Description

iQagent recognizes equipment on your plant floor using QR Codes (Points Of Interest) and displays relevant information, schematics and other resources about it on your tablet device running Windows 10.

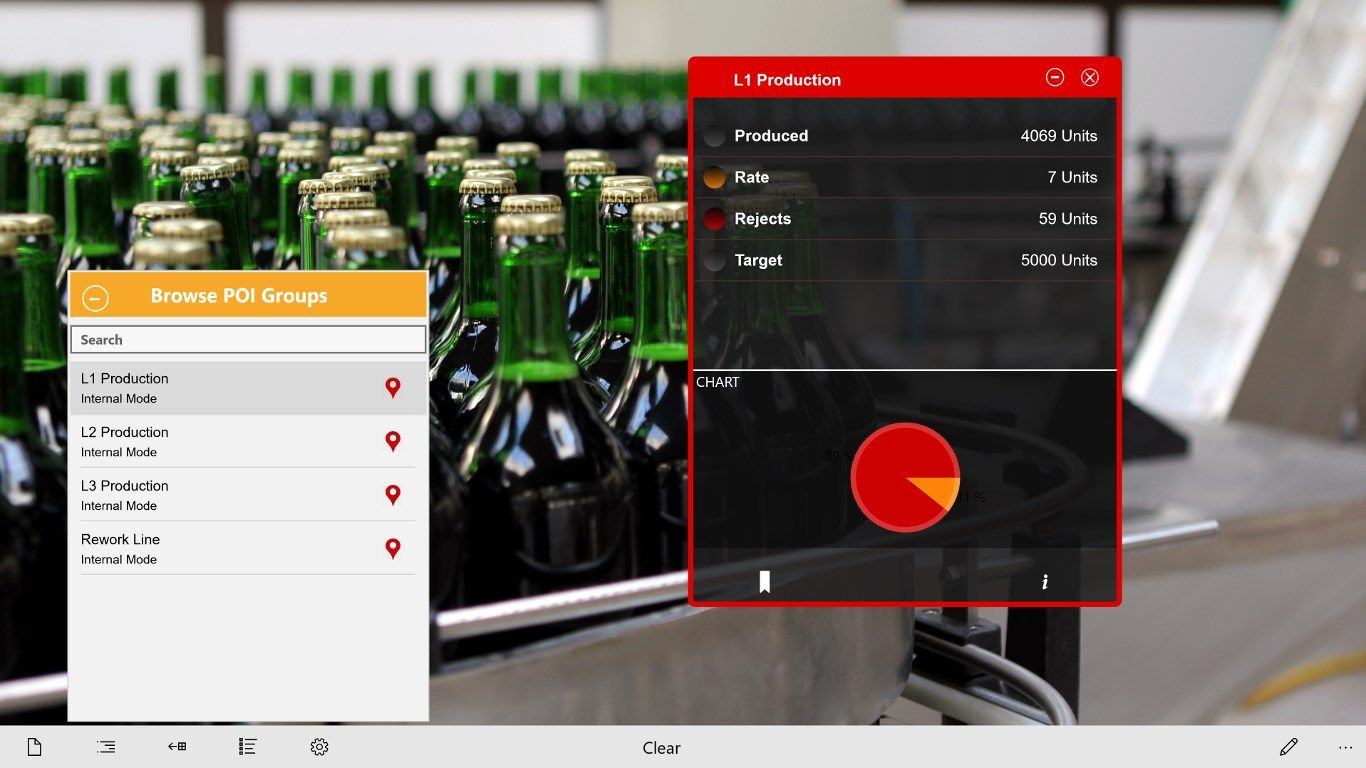

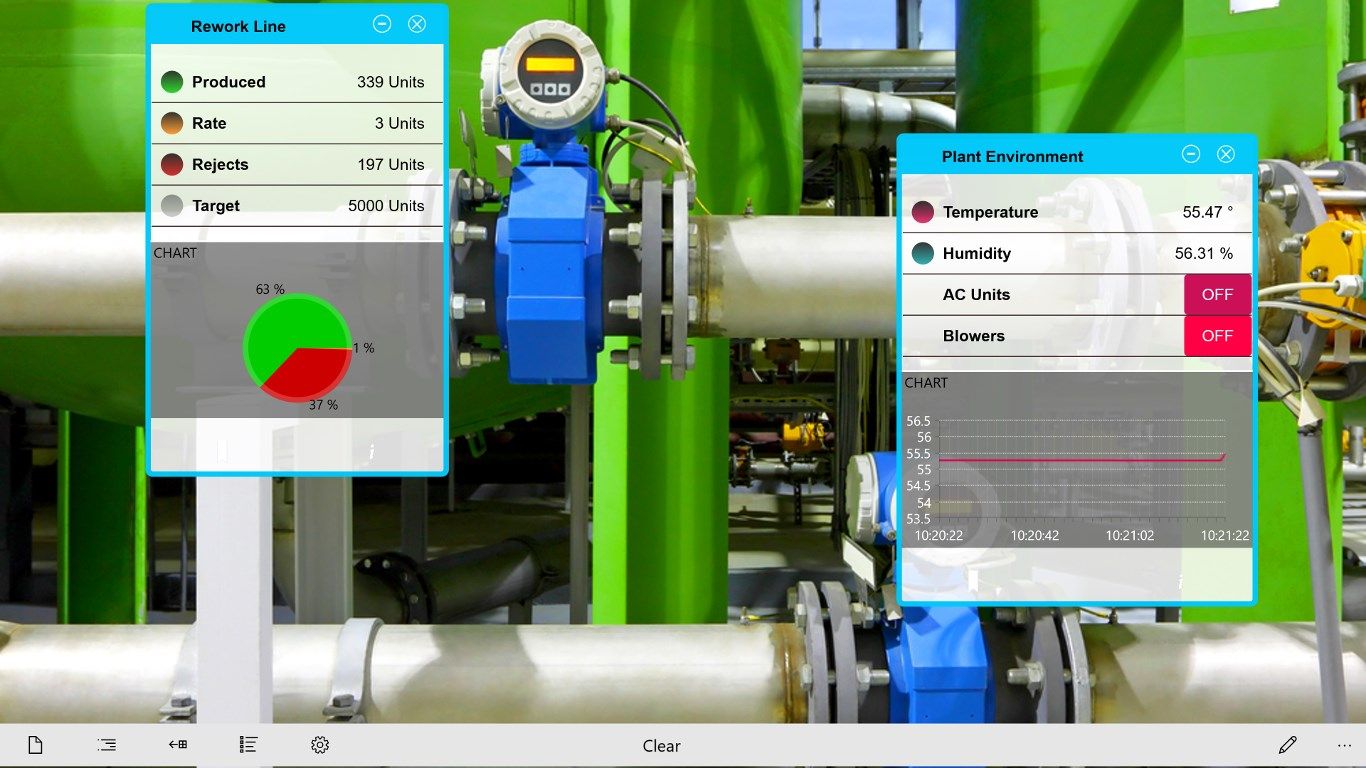

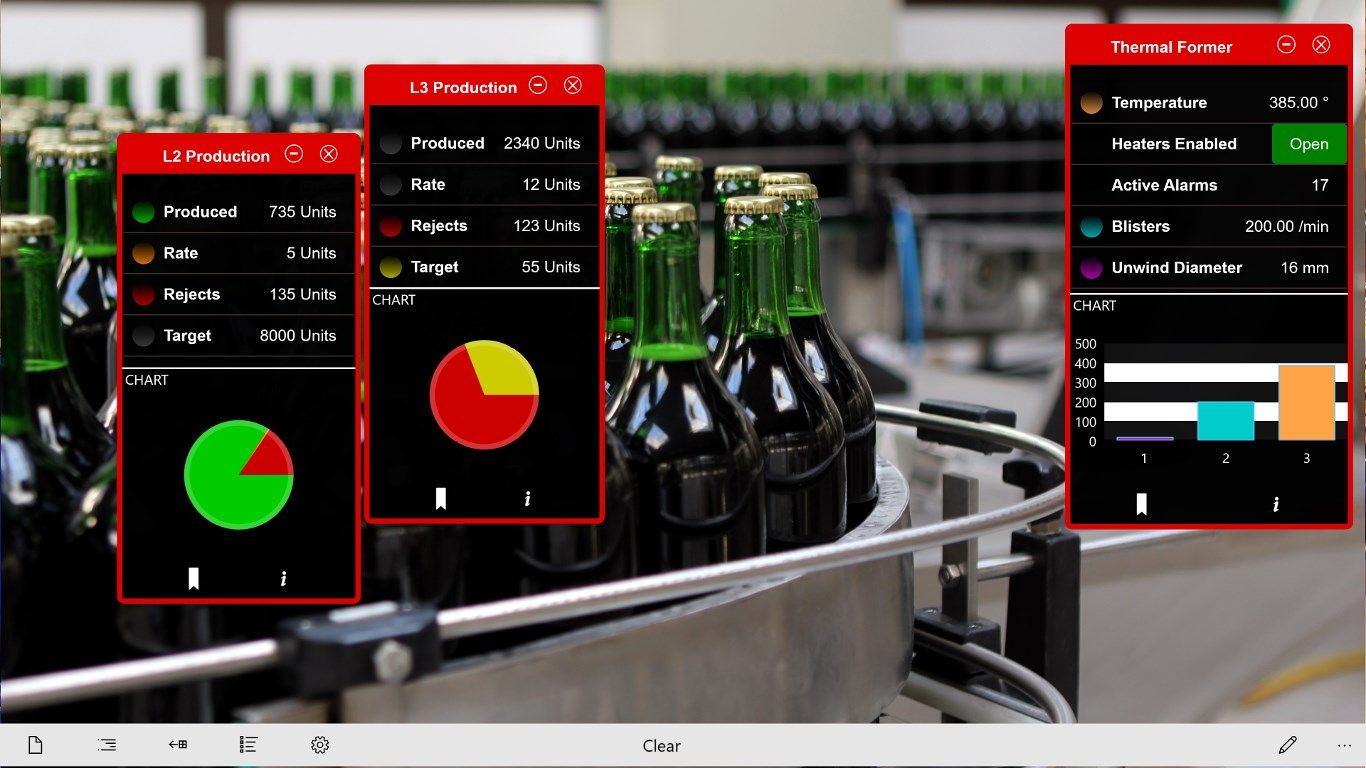

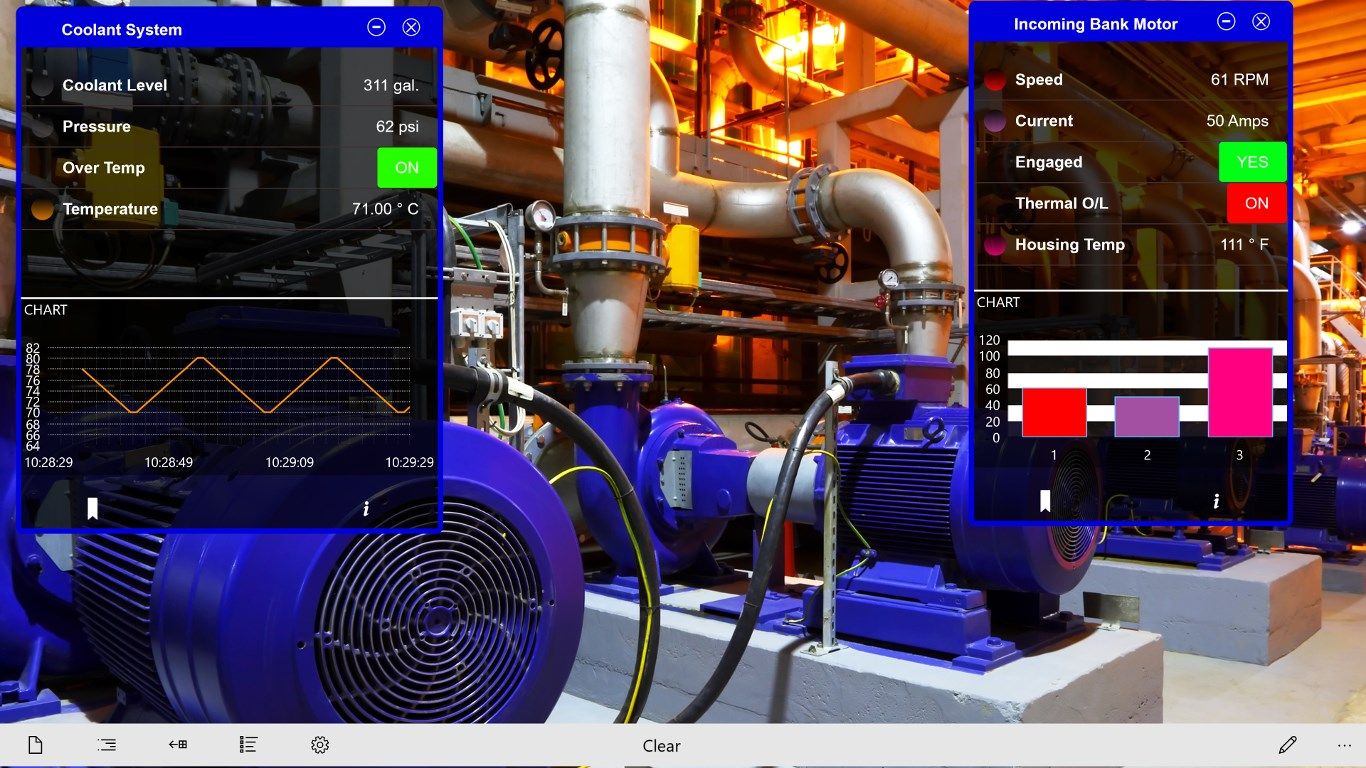

For instance, you could walk up to a assembly line, scan a QR code with your Windows Tablet, and show the number of units produced, production rate, and number of rejects, all live data from your HMI, SCADA, PLC or Database. You can also view preventative maintenance actions and trouble reports from your local systems, or call up production schedules from a database, or email or call a vendor or supervisor.

iQagent is a holistic data display and recorder for industrial and process environments. It will allow you to make your plant floor a data rich environment where you can access live process data, documentation, and resource links on specific machines, equipment, and processes on the plant floor.

Recent Awards:

- Sikorsky Entrepreneurial Challenge, Honorable Mention, 2015.

- Control Engineering Apps For Engineers (Finalist) 2013

- Plant Engineering’s Product Of The Year, Gold Award, 2012

How It Works:

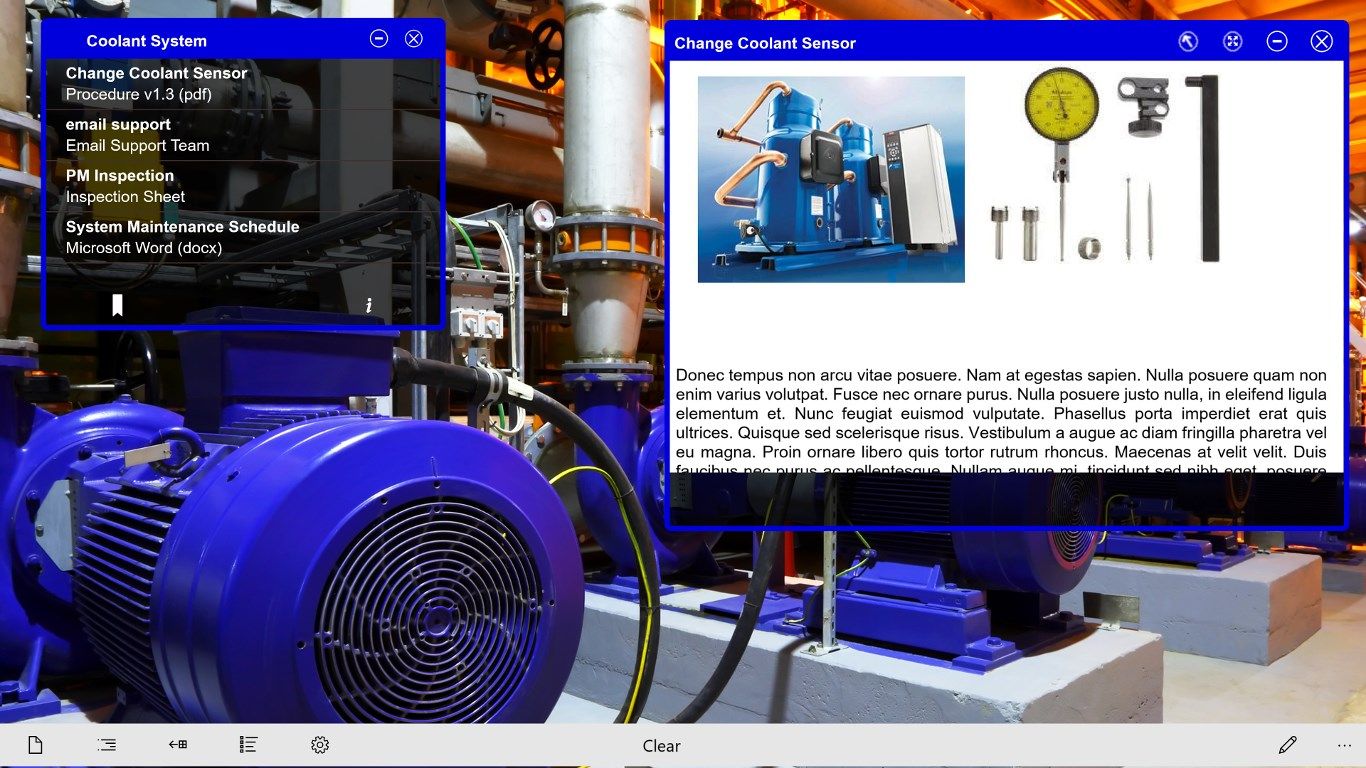

Using the iQagent configuration utility, create and configure Point Of Interest (POIs) for equipment, machines, work cells and processes around your plant. The POI Data View shows live process data you configure by browsing your existing SCADA, HMI, PLC or DCS using OPCUA or ODBC. You can also configure charts to show the data such as trends, bar graphs or pie charts. The POI Info View allows you to associate any document, URL, email address or other resource to allow for quick access.

Next, print each POI’s QR code and place them near the actual equipment or process in the plant or environment.

On the Plant floor, use the iQagent App to scan the QR Codes to show the data views for POI. You can also quickly view any POIs by simply browsing to them. There is even a favorites list for quick access.

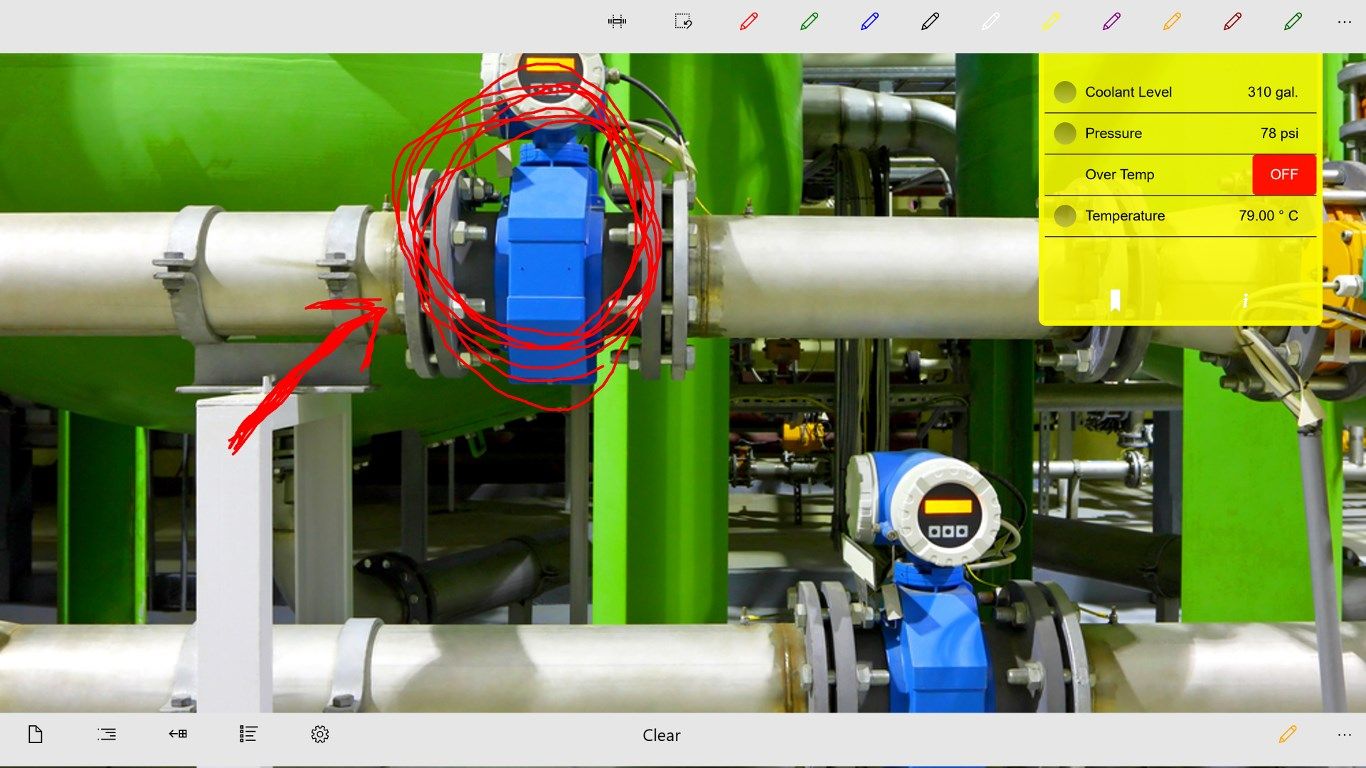

Having problems with your process, or unscheduled downtime? iQagent can help resolve these costly problems quickly! Use our patented Snapshot feature to record the problem, which includes everything on the display: live Data Views, Info Views, video and your annotations directly on the screen. The resulting snapshot is a holistic representation of your process which can be emailed or sent to offsite support personnel who can quickly help identify and isolate the problem without waiting for them to come to the site!

iQagent also works with Microsoft Wireless displays , so the display can be streamed to your conference room’s HDTV, allowing management to review process issues realtime without having to disturb production.

iQagent comes with a full featured demo mode to allow scanning of QR Codes and simulated data and info views. Visit us online for sample QR Codes that work with the demo mode for testing.

Features:

Display POI data and info views anywhere you have a connection to the plant network.

Instant access to relevant data for any configured POI: Live data, charts, documents, URLs, email addresses, work order requests, or intranet data sites.

-

Recognizes equipment on your Plant Floor and displays live data, schematics and other relevant information sabout the equipment.

-

Allows you to record screenshots augmented with live data and send them to remote technical resources for quick analysis.